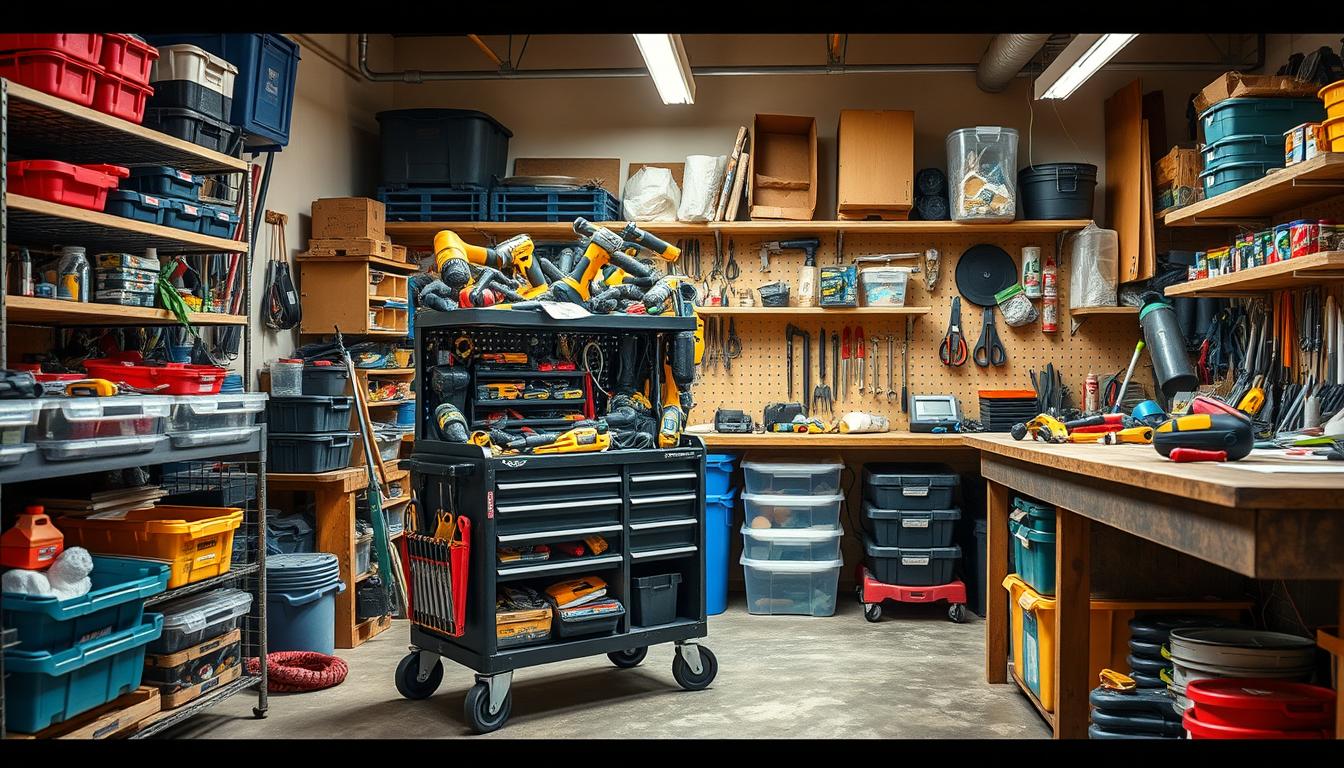

Mobile storage solutions are crucial for any workshop, offering a convenient and organized method to store tools and equipment. A rolling tool cart allows for effortless tool movement, reducing clutter and boosting productivity. This synergy between mobile storage and workshop mobility enhances workspace efficiency.

Rolling carts exemplify mobile storage, enabling quick and easy tool access. By integrating mobile storage into your workshop, you can streamline your workflow and minimize tool search time.

This article delves into mobile storage solutions, focusing on creating rolling tool carts for efficient tool access. We’ll discuss the advantages of mobile storage, the necessary materials and tools for cart construction, and offer a step-by-step guide to designing and building your own cart. We’ll emphasize the importance of workshop mobility and the role of rolling carts in achieving an organized workspace.

Key Takeaways

- Mobile storage solutions improve workshop efficiency and productivity

- Rolling tool carts provide easy access to tools and equipment

- Mobile storage and workshop mobility are essential for a well-organized workspace

- Building a rolling tool cart can be a cost-effective and efficient solution

- Proper design and construction of a rolling tool cart are crucial for optimal performance

Understanding Mobile Storage Benefits

Mobile storage solutions bring many advantages, such as enhanced workshop efficiency, space-saving benefits, and ergonomic improvements. A well-organized tool storage system reduces the time spent searching for tools. This boosts productivity and lowers injury risks. Effective tool organization is crucial, allowing for quick tool access and smoother workflow.

Mobile storage excels in providing portable storage options, making it easy to move tools and equipment around your workshop. This is highly beneficial in large workshops or for projects needing multiple tools. Wheeled storage units stand out, as they can be easily moved to where needed, cutting down on unnecessary movement and strain.

- Improved workshop efficiency through reduced tool search times

- Space-saving advantages, allowing for more efficient use of workshop space

- Ergonomic considerations, reducing the risk of injury and strain

Integrating mobile storage into your workshop can make it more efficient, productive, and safe. Whether you’re a professional contractor or a DIY enthusiast, mobile storage maximizes tool and equipment use.

| Mobile Storage Benefit | Description |

|---|---|

| Improved Efficiency | Reduced tool search times, increased productivity |

| Space-Saving | More efficient use of workshop space, reduced clutter |

| Ergonomic Considerations | Reduced risk of injury and strain, improved worker safety |

Essential Materials and Tools for Cart Construction

To build a rolling tool cart, you’ll need to gather the necessary materials and tools. This includes lumber, wheels, and hardware, as well as tools like saws, drills, and sanders. Having a clear plan and design before starting the project is crucial. Creating a customized storage cart plan can help you achieve your specific needs.

When it comes to mobile storage, it’s essential to consider the type of materials you’ll be using. For example, you may want to use durable wood or metal for the frame, and sturdy wheels that can support the weight of your tools. You’ll also need to think about the size and capacity of your cart, as well as the layout of the storage compartments.

Here are some key materials and tools you’ll need to get started:

- Lumber (e.g. wood or metal) for the frame

- Wheels and casters for mobility

- Hardware (e.g. screws, nails, hinges)

- Tools (e.g. saws, drills, sanders)

- A clear plan and design for your storage cart plans

By having all the necessary materials and tools, you’ll be able to create a functional and efficient mobile storage solution that meets your needs. Remember to consider your specific requirements and create a customized storage cart plan to ensure your cart is tailored to your needs.

With the right materials and tools, you’ll be well on your way to building a rolling tool cart that provides convenient and accessible mobile storage for your tools and equipment.

| Material | Quantity | Purpose |

|---|---|---|

| Lumber | 4-6 pieces | Frame construction |

| Wheels | 4-6 | Mobility and support |

| Hardware | Varies | Frame assembly and attachment |

Designing Your Rolling Tool Cart

Designing a rolling tool cart involves several key considerations to meet your needs and improve workshop mobility. The cart’s size and capacity must align with your tools and workshop space. Reflect on your typical projects and most-used tools to choose the right size and capacity.

A well-designed cart can significantly enhance tool organization and workflow. Choose durable wheels that support the weight of your tools and won’t harm your workshop floor. This ensures smooth movement, even when the cart is fully loaded.

Size and Capacity Planning

To find the perfect size and capacity, list your tools and their sizes. Consider the storage compartments you’ll need, like drawers, shelves, and cabinets. Think about your workshop’s workflow and ergonomics. Design your cart to fit seamlessly into your setup.

Wheel Selection Guidelines

When picking wheels, focus on weight capacity and durability. Opt for high-quality materials and heavy-duty design. Also, choose a suitable brake mechanism to keep the cart in place when stationary.

Storage Compartment Layout

The layout of storage compartments depends on your tools and cart size. Use a mix of drawers, shelves, and cabinets for maximum space. Ensure easy access to your tools for quick retrieval.

| Tool Type | Storage Compartment |

|---|---|

| Hand tools | Drawers |

| Power tools | Shelves |

| Fasteners and hardware | Cabinets |

By adhering to these guidelines, you can create a rolling tool cart that suits your needs. It will enhance your workshop’s mobility and tool organization.

Framework Construction Techniques

With your design and plan in place, it’s time to start constructing the framework of your rolling tool cart. This involves cutting and assembling the lumber, attaching the wheels, and adding any additional support structures. The key to a sturdy cart is using durable materials that can withstand heavy use, making it ideal for portable storage solutions.

A well-built framework is essential for a reliable wheeled storage unit. Consider the following steps to ensure a solid foundation:

- Cut the lumber according to your design specifications

- Assemble the frame using screws or nails

- Attach the wheels to the frame, making sure they are securely fastened

- Add any additional support structures, such as shelves or drawers

By following these steps and using high-quality materials, you can create a robust and reliable rolling tool cart that meets your portable storage needs. Remember to consider the weight capacity and mobility of your cart to ensure it can handle heavy tools and equipment. This makes it an ideal wheeled storage solution for your workshop or garage.

| Material | Weight Capacity | Durability |

|---|---|---|

| Lumber | 500 lbs | High |

| Steel | 1000 lbs | Very High |

| Aluminum | 750 lbs | High |

Installing Wheels and Support Systems

Rolling carts are vital in any workshop, boosting productivity with their mobility. To ensure your cart moves smoothly, choosing the right wheels and support systems is key. This means picking between swivel or rigid casters and installing them correctly. This setup is crucial for easy movement and handling.

Effective mobile storage balances mobility with stability. Weight distribution is crucial here, as uneven weight can destabilize the cart. To maintain balance, it’s important to consider weight distribution principles. This ensures the cart stays stable and balanced.

Caster Types and Installation

- Swivel casters for smooth movement and maneuverability

- Rigid casters for stability and support

Weight Distribution Principles

Understanding weight distribution is essential for your cart’s stability and mobility. Even weight distribution prevents tipping and keeps the cart stable and balanced.

Brake Mechanism Options

Installing a reliable brake is crucial to keep the cart stationary when not in use. You can choose from lever-activated or foot-activated brakes, depending on your needs and preferences.

Building Storage Compartments and Drawers

Now that the framework and wheels are set, it’s time to focus on tool organization. Designing storage compartments should consider the size and shape of your tools. This ensures a snug fit, preventing damage and maximizing your portable storage unit’s space.

A well-planned storage system is crucial for efficient workshop operations. By using storage cart plans tailored to your needs, you can streamline your workflow and reduce clutter. Here are some tips to get you started:

- Assess your tool collection and group similar items together

- Measure your tools to determine the ideal compartment size

- Consider adding drawers, shelves, or cabinets to your storage cart

By following these guidelines and incorporating your storage cart plans, you can create a customized storage solution. Remember to prioritize tool organization and maximize your portable storage capacity. This ensures an efficient and productive workshop experience.

With a well-designed storage system, you’ll quickly find the tools you need. This saves time and reduces frustration. Investing in a high-quality portable storage unit and implementing effective tool organization strategies will elevate your workshop. It will lead to greater productivity.

Adding Custom Features and Accessories

To boost your rolling tool cart’s functionality, think about adding custom features and accessories tailored to your needs. Tool holders and organizers, like pegboards and tool trays, ensure your tools are always within reach. This setup enhances your mobile storage and boosts workshop efficiency.

Some common custom features for rolling carts include:

- Tool holders and organizers, such as pegboards and tool trays

- Power strip integration to keep your tools charged and ready to use

- Locking mechanisms to secure your tools and prevent theft

When designing your rolling tool cart, remember the value of mobile storage and workshop mobility. Custom features and accessories help create a solution that fits your needs perfectly. This approach improves your workshop experience.

To further enhance your rolling tool cart, consider adding a vice or a work surface. These additions provide a stable, convenient workspace for efficient task completion. Investing in a high-quality cart with custom features and accessories elevates your mobile storage solution and workshop mobility.

| Custom Feature | Description |

|---|---|

| Tool Holders and Organizers | Keep tools within easy reach and promote workshop mobility |

| Power Strip Integration | Keep tools charged and ready to use |

| Locking Mechanisms | Secure tools and prevent theft |

Maintenance Tips for Mobile Storage Units

To maintain your portable storage units, regular upkeep is crucial. This involves caring for the wheels and protecting the storage surfaces from damage. By adhering to these guidelines, your storage cart plans will be executed efficiently, and your units will operate smoothly.

It’s essential to clean and lubricate the wheels regularly to prevent rust and corrosion. This is more critical for outdoor units exposed to the elements. Also, ensure to check and tighten the hardware on your storage cart to avoid damage or accidents.

Wheel Care Guidelines

- Clean the wheels regularly to prevent dirt and debris buildup

- Lubricate the wheels to prevent rust and corrosion

- Check the wheels for signs of wear and tear, and replace them as needed

Storage Surface Protection

To safeguard the storage surfaces of your portable units, consider applying a waterproof coating or sealant. This measure helps prevent damage from moisture and spills. Regular cleaning and inspections of the surfaces are also necessary to avoid dirt and debris accumulation.

Adhering to these maintenance tips can extend the lifespan of your portable storage units. Whether for a home workshop or commercial use, regular maintenance is crucial for optimal performance. It ensures you get the most out of your investment.

| Maintenance Task | Frequency |

|---|---|

| Wheel cleaning and lubrication | Monthly |

| Hardware check and tightening | Quarterly |

| Storage surface cleaning and inspection | Weekly |

Conclusion

Building a rolling tool cart is a rewarding project that can transform your workshop. It offers mobile storage and organization solutions. By following the steps in this article, you can create a customized cart that meets your needs. This will boost your productivity and give you a sense of pride in your work.

When creating your mobile storage unit, focus on functionality, accessibility, and ergonomics. Consider the size, wheel selection, and compartment layout. This ensures your cart becomes a vital tool in your workshop. Adding custom features and accessories can also enhance its versatility and convenience.

With the knowledge from this article, you’re ready to make your workshop more efficient and organized. Create a mobile storage solution that reflects your unique needs and preferences. Enjoy the benefits it will bring to your daily work.