Every DIY project needs the right tools to succeed. Whether you’re building a bookshelf, fixing a wall, or making furniture, the right tools are key. Tools like tape measures, rulers, and levels help you get it right.

This guide will show you how the right tools can help your build with confidence. The right measuring tools ensure your projects turn out just as you imagined.

Key Takeaways

- Precision tools prevent errors in DIY projects.

- Basic tools like tape measures and levels are must-haves.

- Different projects require different types of measuring tools.

- Regular care keeps tools accurate and reliable.

Getting Started with Measuring Tools

Starting any DIY project needs the right tools for success. It’s important to pick tools that match your needs. Precision and durable tools are key for accurate and lasting results.

Essential Features to Look For

- Accuracy: Choose tools with precision measuring like laser levels or digital displays.

- Durability: Go for durable measuring devices made from steel or strong plastics.

- Ergonomics: Pick tools with comfy grips and clear signs for easy use.

Variety of Tools for Different Projects

Every project needs its own tools:

- Tape measures: Steel tapes for tough jobs.

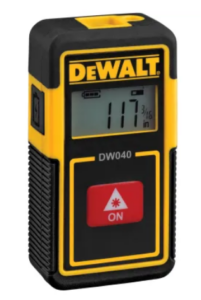

- Laser distance measurers: Great for big areas, perfect for home updates.

- Calipers: For small tasks like woodworking or electronics.

Budget and Quality Considerations

Quality tools save time and money in the long run. Brands like Stanley and DeWalt offer durable measuring devices at different prices. Cheap tools might not last, while mid-range ones offer good value and precision measuring.

Choosing the Perfect Measuring Tools for DIY Projects

Choosing the right tools is key for a smooth project. Start by making a plan to find affordable measuring tools that fit your needs. Here are some steps to help you find what you need.

Tool Selection Checklist

- First, figure out what kind of project you’re doing (like woodworking or plumbing)

- Then, decide how much you want to spend to find affordable measuring tools that are good quality

- Think about what features you need, like laser alignment or digital readouts, based on your project

Product Recommendations:

Tape Measure: Stanley PowerLock 25 ft Tape Measure

Laser distance measurer: DEWALT 40 ft Pocket Laser Distance Measurer

Calipers: Digital Caliper 0″ – 6″

Measuring Accuracy: Techniques and Best Practices

Getting accurate measurements is essential for DIY projects. First, check your tools before starting. Use straight edges and clean surfaces to avoid mistakes.

Always make sure tools are aligned right. Angled readings can lead to errors.

- Use cross-verification: Compare results with two tools to confirm accuracy.

- Calibrate regularly: Digital tools like laser levels often include self-calibration features.

- Read instructions: Follow guidelines for tools like digital calipers to ensure proper technique.

| Method | Type | Accuracy | Best Use |

|---|---|---|---|

| Tape Measure | Traditional | ±1/16″ | Carpentry, layout marking |

| Laser Distance Meter | Innovative measuring solutions | ±0.02″ | Room layouts, complex angles |

| Caliper | Hybrid | ±0.001″ | Small part measurements |

Keeping tools in good shape is important. Clean laser tools and check for loose parts weekly. For innovative measuring solutions, apps like MeasureKit Pro can help.

Always write down your measurements. This helps avoid mistakes. Use the same tool for a project to keep things consistent.

If you’re unsure, check the manual or online tutorials. Small changes in how you measure can make a big difference!

Maintaining Your Measuring Tools for Longevity

Regular upkeep keeps your tools precise and reliable. It prevents costly mistakes and extends their life. Follow these steps to keep rulers, levels, and digital devices in top shape.

Cleaning and Calibration Tips

Begin by wiping down tools after each use. Use a soft cloth with mild soap to remove dirt. For digital tools like laser measures, check the manual for cleaning specifics.

Measuring calibration is essential—check accuracy monthly with a known reference. If a tape measure bends, straighten it carefully to avoid warping. Many brands offer calibration guides online.

Proper Storage Techniques

- Store tools in dry areas to prevent rust or moisture damage.

- Hang tape measures to avoid kinking the tape.

- Use a toolbox with dividers to keep tools separated and safe.

Troubleshooting Common Issues

If readings drift, recalibrate the tool. Loose parts? Tighten screws gently. For cracked tools, replace them immediately.

Always compare measurements against a trusted standard to spot inconsistencies early.

Comparing Traditional and Modern Measuring Tools

Choosing between traditional measuring methods and tech-driven options depends on your project needs. Let’s break down the differences:

- Traditional tools like tape measures and rulers offer simplicity and reliability. No batteries needed!

- Modern devices such as laser distance finders or digital calipers provide precision and speed, ideal for complex tasks.

Pros and Cons of Each Approach

Old-school tools shine in basic tasks but lack advanced features. Tech integrated measuring systems reduce human error but may require learning curves. Consider budget and skill level when deciding.

When to Upgrade Your Tools

Upgrade if you encounter these scenarios:

- Repetitive tasks demanding high accuracy (e.g., furniture building)

- Projects requiring remote data sharing (e.g., contractor collaborations)

- Worn-out tools showing consistent inaccuracies

Integrating Technology into Your DIY Projects

Mix both worlds! Use a smartphone app with a steel tape measure for layout work. Brands now offer hybrid tools combining analog and digital features. Start small—add one tech upgrade at a time to see what works best for your workflow.

Conclusion

Mastering accurate measurement techniques is key to turning DIY dreams into reality. Whether you’re working with traditional tape measures or high-tech laser levels, the right tools and methods ensure every project stays on track. Remember to pick durable options, keep them well-maintained, and balance old and new methods to suit your needs.

Perfect cuts and precise angles rely on consistent use of accurate measurement techniques. Even small errors can throw off results, so investing in quality tools and proper training pays off in the long run. Explore options like laser measures or Stanley’s PowerLock tape measures to find what works best for your style.

As you take on new projects, let this guide remind you that precision isn’t just about tools—it’s about smart choices and practice. With the right approach, every measurement becomes a step closer to flawless results. Happy building!